NS - type I X-ray Online Zinc Layer Thickness Gauge

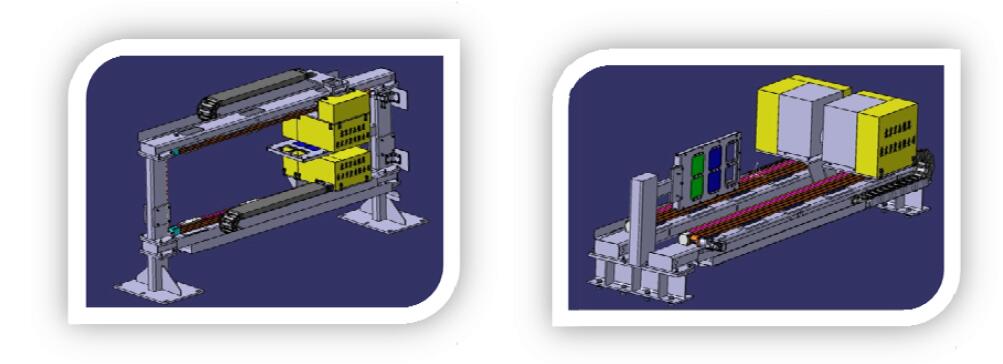

Figure 1 NS ‐ type I X-ray online zinc layer thickness gauge field operation schematic diagram

Product application:

Suitable for galvanized zinc, aluminum, zinc aluminum alloy production line, such as online contactless inspection, implement copperplating layer according to user requirements can be realized now to participate in the AGC control control;

Second, the installation method:

Horizontal and vertical try structure;

Figure 2: installation: lie horizontal structure Figure 3: installation: vertical structure

Three, the performance characteristics:

, NS ‐ type I adopt adopt international advanced technology into the X-ray inspection of detection.

Using O type intelligent scanning and two synchronous displacement sensor, guarantee the synchronicity of the screening test;

, three kinds of control system model; Three little detection mode, single point detection model and continuous sweep scanning mode, make make detection data is more accurate and comprehensive.

, do not contact with strip steel sheet surface, warmed up after can be put into use, does not affect the sound production by the user.

, short response time, measurement values accurately.

Using low voltage pressure, reveal that the minimum amount of radiation dose, meet the national standard of free radiation levels.

, adopt servo motor to complete the main main drive control; precision is higher.

The data report, diverse work function, integrated powerful statements table management system, can real-time query to testing and recorded data information; May realize the data now always display and record the record data column chart automatic statistics, trends, Desmond tutu and display.

Using the WINDOWS operating system, simple and practical, easy to maintain.

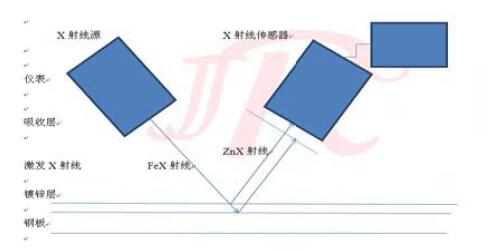

Figure 4: NS ‐ type I fluorescent X-ray line online coating layer thickness gauge principle diagram

Beijing Jingjie Royce & Technology Development Co., Ltd. All rights reserved 京ICP备06040483号 Enterprise mailbox portal

中文

中文 EN

EN RU

RU